Up to the time of the introduction of the machine invented by Lyman R. Blake in 1858, which afterwards became known as the McKay Sewing Machine, shoes had been made almost entirely by hand. Gordon McKay, whose name latter became associated with the shoe, purchased the patent rights from Blake and after many experiments was able to introduce this process as a practical method for making shoes.

Originally and for a long period thereafter, McKay shoes were wholly tack-lasted. The last used for this process has a metal bottom with four small openings through which tacks are temporarily driven to hold the insole in place prior to and during the lasting of the upper. These tacks are removed after the shoe is completely lasted and pounded and before the outsole is positioned.

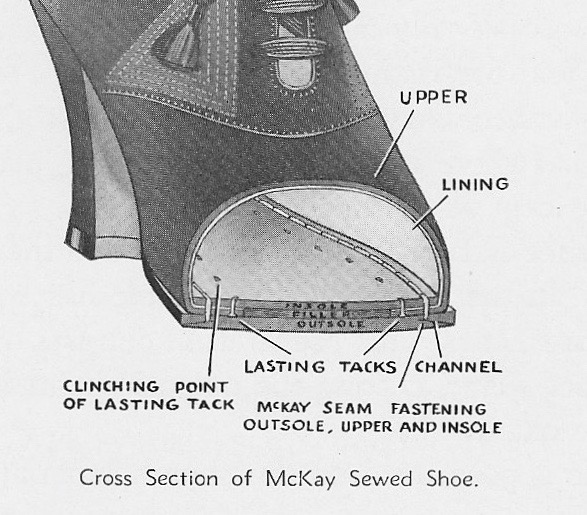

After the insole is correctly positioned on the last, the upper and linings are pulled tightly over the last and fastened to the under surface of the insole, by means of tacks which actually penetrate the insole and are clinched permanently against the metal bottom of the last.

Such a clinch is a short turning back or stubbing of the point of the tack, afterwards visible inside the shoe only as a small speck of metal, but strong enough to make the tack a fixture for the life of the shoe.

Some manufacturers have adopted other lasting methods, particularly in women's McKay sewn shoes. Among the newer methods used are Littleway staple lasting of shank and forepart, cement toe lasting, and occasionally tack and staple shank lasting combined with cement forepart and toe lasting. Whenever tacks are not used in shank or forepart, it is unnecessary to have metal-bottomed shank and forepart to the last, as there is no metallic fastening penetrating the insole to be clinched, except at the heel seat.

After the shoe is lasted, the shank piece and the bottom or forepart filler are added. In the meantime the outsole has been prepared in the stock fitting department. This preparation consists of rounding the outsole to the proper shape, cutting the outsole channel, sole molding and turning back the channel lip.

The outsole is positioned on the shoe bottom and held temporarily in place by means of staples or cement. The shoe is now ready for sole attaching by means of the McKay sewing. Prior to sewing, however, the last is removed from the shoe.

The McKay stitch is a chainstitch and passes through the respective thicknesses of outsole, upper, lining and insole. This seam is so positioned as to lie between the clinched lasting tacks and the edge of the insole.

After McKay sewing, the outsole channel is cemented and laid back to its original position, thereby covering the stitches. The shoe is then leveled on a machine designed with a steel foot which goes inside the shoe and a forming mold on the outside of the sole. The required pressure is applied to smooth the insole and assure a comfortable interior.

Re-lasting is then sometimes done and subsequent operations in completing the shoe include heel attaching, heel shaving and breasting, heel staining and finishing for leather heels and attaching for wood heels, edge trimming, inking or staining the edges, burnishing or setting the edges and cleaning the upper. For additional comfort and appearance the insole is covered with a sock lining. After these operations are completed the shoe is given a final inspection and is then ready for packing.